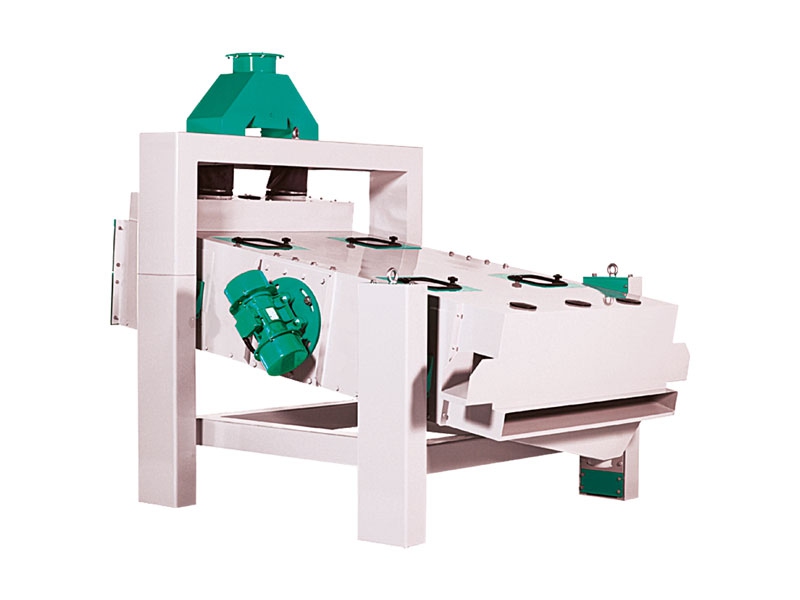

Used in pre-cleaning and cleaning sections of milis and grain cleaning factories. Metal body consists of two profil cases. Product spreads on sieves by the vibration of vibro motors. Waste products as straws, trash, spikes etc move to outlet by vibration. Cleaning of sieves occuring by rubber balls inside the sieves. Slope of sieves can be calibrated by calibration handles. Flow control occurs by mica glasses. Sieves have the easily dismantling specifications.

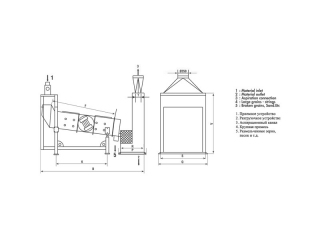

| TYPE |

A |

Φ |

B |

C |

D |

E |

F |

G |

H |

K |

P |

R |

S |

T |

Φ |

V |

| STR 100x150 |

120 |

120 |

2270 |

140 |

1710 |

1080 |

1500 |

1360 |

1560 |

1740 |

535 |

450 |

1000 |

120 |

1080 |

1500 |

| STR 100x200 |

150 |

150 |

2270 |

1410 |

1710 |

1080 |

2000 |

1360 |

1560 |

1740 |

535 |

450 |

1000 |

120 |

1080 |

1500 |

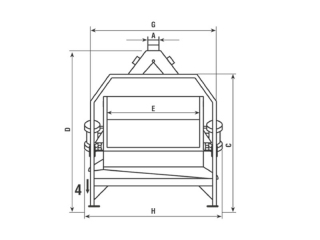

| TYPE |

Air Volume (m³/ min) |

Screens ' in (cm) |

lntermediate Receiver (Φ cm) |

Capacity (t/h) |

Weight (kg) |

|

Elevator |

Cleaning |

Width |

Lenght |

Mono Syklon |

Elevator |

Cleaning |

Net |

Gross |

| STR 100x150 |

70 |

50 |

100 |

100 |

30 |

15 |

8 |

540 |

740 |

| STR 100x200 |

90 |

50 |

100 |

2x100 |

40 |

25 |

12 |

550 |

800 |