From the inlet the cereal reaches the cover inside and is attracted in the processing area by the inclined paddles of the speedy rotor. The peeling efifect is due to this operation, which detaches and removes dust and dirt, beards, germ and the extemal woody skin of the cereal grain. While the sound grains are not damaged, and, due to the paddle inclination, are conveyed to the outlet, the empty and the eventual anthrax grains are broken and crushed in such a way that they can pass through the sifting cover together with the peeling screenings. The latter get out of the machine through the collecting hopper. Dust and pollards are exhausted and seperated in the filter. Maintenance presents no problems, it consists simply in checking and, it necessary, replace the cover, and in the drive belt tension.

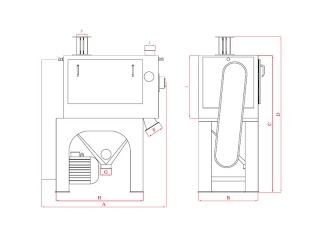

| MODEL | DIMENSIONS (mm) | MOTOR (kw) | WEIGHT (kg) | CAPACITY (T/h) | |||||||||

| A | B | C | D | E | F | G | H | I | J | ||||

| STR 30/65 | 1240 | 550 | 1405 | 1515 | 120 | 120 | 120 | 900 | 120 | 600 | 7,5 | 580 | 5-7 |

| STR45/80 | 1470 | 700 | 1615 | 1804 | 150 | 150 | 120 | 1075 | 120 | 740 | 15-18 ,5 | 860-880 | 12-15 |